Understanding Color Measurement and Its Applications

Color plays a crucial role in various industries.

Achieving color consistency is a challenge that industries like decorative, manufacturing, and design often face. Whether it's ensuring product uniformity across batches or translating a creative vision into reality, precise color measurement is key.

This page explores the science of color measurement, detailing how it is performed and the tools used. Discover CPE’s expert services in color measurement and formulation, ensuring your products are presented in the exact shades you need across different materials and applications. Whether you need fan decks, color charts, or bespoke color solutions, CPE is here to bring your color vision to life.

Show Me CPE's Products and Services

What is Color Measurement?

In many industries, maintaining consistent colors across different materials and applications is not just a preference—it's a necessity.

Color measurement is a scientific approach to quantifying and analyzing the colors of different surfaces. Unlike subjective visual observation, color measurement provides objective data about a color’s properties. This process uses specific instruments to evaluate the color and helps industries to maintain color consistency across their products.

Essentially, color measurement helps identify, communicate, and match colors more precisely.

Color measurement works by capturing color as it is perceived by the human eye or through digital means, in various color spaces.

The two main types of color measurement are:

-

Reflective measurement: used for solid objects and surfaces, where the instrument measures how much light is reflected from the surface.

-

Transmissive measurement: used for transparent or translucent materials, this type measures the light that passes through a material.

How Can I and My Company Benefit From This?

How Does Color Measurement Work?

The process of color intensity and density measurement involves using specialized tools to detect color data. These tools can identify the intensity and type of light absorbed or reflected by a surface, giving a numerical representation of the color.

This process is crucial for industries where color consistency is key, such as printing, textiles, automotive, and manufacturing.

Color data is often represented in different color spaces:

-

RGB (Red, Green, Blue): standard for digital screens.

-

CMYK (Cyan, Magenta, Yellow, Key/Black): used in printing.

-

LAB Color: describes color as perceived by humans, focusing on lightness and color opponents.

Consider this example: imagine you're inspired by a unique shade of blue on a ceramic vase. Transforming this inspiration into a color standard across your product line can feel daunting. With advanced tools and expertise, these obstacles are simplified, enabling you to turn inspiration into precise, repeatable results.

Instruments for Measuring Color

Several tools are designed to provide accurate color measurement:

-

Spectrophotometers: these are advanced instruments that measure the intensity of light across a spectrum. They provide detailed and accurate data about a color's properties, helping to replicate exact colors.

-

Colorimeters: less complex than spectrophotometers, colorimeters are used for color temperature measurement, identifying the amount of light in the red, green, and blue regions of the spectrum. They are commonly used for simpler color matching tasks.

-

Densitometers: primarily used in the printing industry, densitometers measure the optical density of a surface, providing crucial data for quality control.

Choosing the right tool ensures you get the data you need to resolve your specific color challenges.

Industries where precision ensures quality

Color measurement plays a crucial role across numerous industrial sectors, where appearance control is essential to meet product specifications, uphold brand identity and ensure customer satisfaction. Before exploring CPE’s tailored solutions, it’s important to consider how color measurement is applied in different production and manufacturing environments.

Below are four key industries where accurate color control supports critical processes and outcomes:

1. Color measurement solutions for textiles

In textile manufacturing, managing color with high precision is fundamental, from dyeing raw materials to evaluating finished fabrics. Color measurement systems help maintain shade uniformity across batches, align output with design expectations, and minimize the risk of costly non-compliance. These tools are vital for both process control and quality assurance in a fast-moving, style-driven sector.

2. Color measurement for auto manufacturer

Within the automotive industry, even slight color deviations can affect perceived quality. Color measurement technologies enable manufacturers to monitor and manage variations across painted surfaces, plastics, and interior components, regardless of material or supplier. Accurate, repeatable measurement is essential to achieve uniformity across entire vehicles and to meet the exacting standards of global OEMs.

3. Pharmaceutical color measurement

In pharmaceutical production, color serves not only an aesthetic function but also a practical one, often indicating proper formulation or integrity. Measurement systems are used to verify the appearance of tablets, capsules, powders and liquids, ensuring batch consistency, supporting regulatory compliance, and helping to identify formulation issues at an early stage.

4. Color measurement for industrial paints and coatings

For manufacturers of coatings used in construction, infrastructure, and heavy equipment, color accuracy is closely tied to both performance and professional standards. Whether applying to metals, plastics or composites, measurement tools are used to formulate, test, and validate shades with precision. They help ensure that coatings perform as intended, visually align with specification, and remain consistent across multiple substrates and production environments.

Understanding how color measurement is applied in these sectors provides the foundation for choosing the right tools and technologies. CPE addresses these needs with a comprehensive range of industry-specific solutions designed to integrate seamlessly into your workflow.

CPE's Expertise in Color Measurement Services

Whether you're a creative professional or a production expert, achieving reliable color results is within reach. The key is working with a partner who understands your needs, offers tailored solutions, and ensures seamless integration into your workflow.

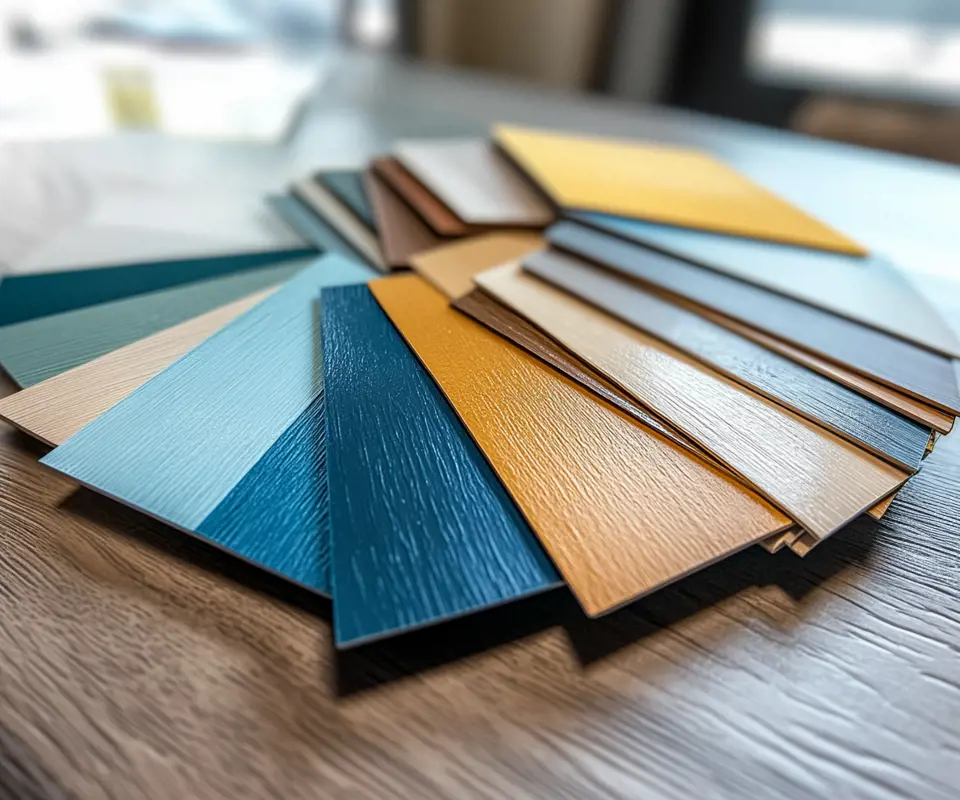

CPE specialises in color measurement designed to help you achieve precise color formulation for your products. From color fan decks to color books, CPE provides solutions tailored to your needs.

Full-page Fan Decks

These practical tools are ideal for technical and professional settings. Available on various materials like paper, wood, aluminum, and PVC, they allow for complete color presentation and can be customized in different formats.

Stripe-coated Fan Decks

A more condensed tool that features multiple color stripes on a single page. They enable quick and easy comparison of many colors while maintaining high visibility.

Color Books

Spiral-bound or in ring binder form, these color books provide multiple hues and effects for easy reference and communication of colors.

Color Charts and Posters

Versatile printed materials that range from single cards to multi-page folders and large wall formats. They display color chips that can show different finishes and effects.

Color brochures

Containing a wide range of colors in different shades, tones, and intensities, catalogs are used across various industries to display options for decorative, automotive, or construction applications.

CPE’s production process ensures the highest quality standards by involving specialists at every step. Once a client provides an original color standard, CPE uses state-of-the-art equipment to mix and verify the shades, applying the color to samples using production processes like coating or spraying.

Formulation Services

CPE's team of experts formulates water-based or solvent-based paints according to the client’s needs. The colors are sprayed on panels through either manual or automated methods to match the intended application.

Achieve Accurate Color Measurement and Formulation for Your Products with CPE